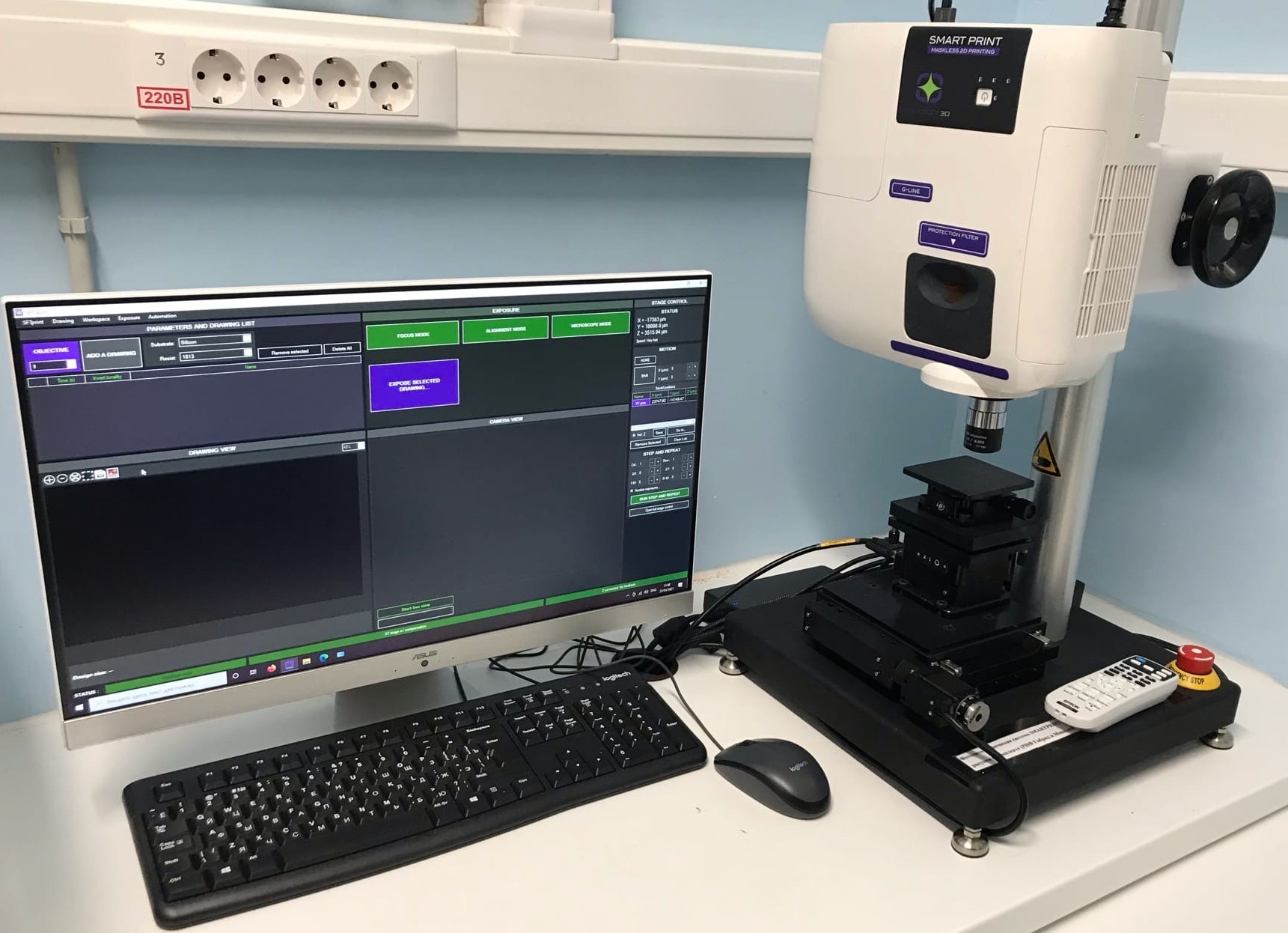

The maskless lithography unit is designed to work on 100 mm plates. The laser lithography system allows you to work without a photomask and was specially designed for research centers and small-scale production. Ergonomic design and desktop performance allows it to be implemented in any production at lithography and micro-assembly shops. Users around the world have already appreciated this system and produced high quality products.

Features of the installation of maskless lithography

The SmartPrint Standart model without masking lithography can work in both the micron and nanometer range. The maskless lithography system allows you to work with 76, 100 mm plates and 60 x 48 substrates. The laser lithography system has a desktop design and can be installed in laboratories and small industries.

Installation software for maskless laser lithography

The software allows you to implement lithography and control the process by setting the necessary parameters and requirements. The points below show the main characteristics of the laser lithography system. The lithography system allows you to save images and data in known formats and resolutions. Thanks to the motorized stage, the user has the opportunity to set the process parameters and control the lithography.

|

Parameter |

Value |

|

Minimum size |

1.5 microns |

|

Plate size |

Maximum diameter 100 mm |

| Exposed area size |

70 mm × 70 mm |

| Скорость письма |

77 mm² / min |