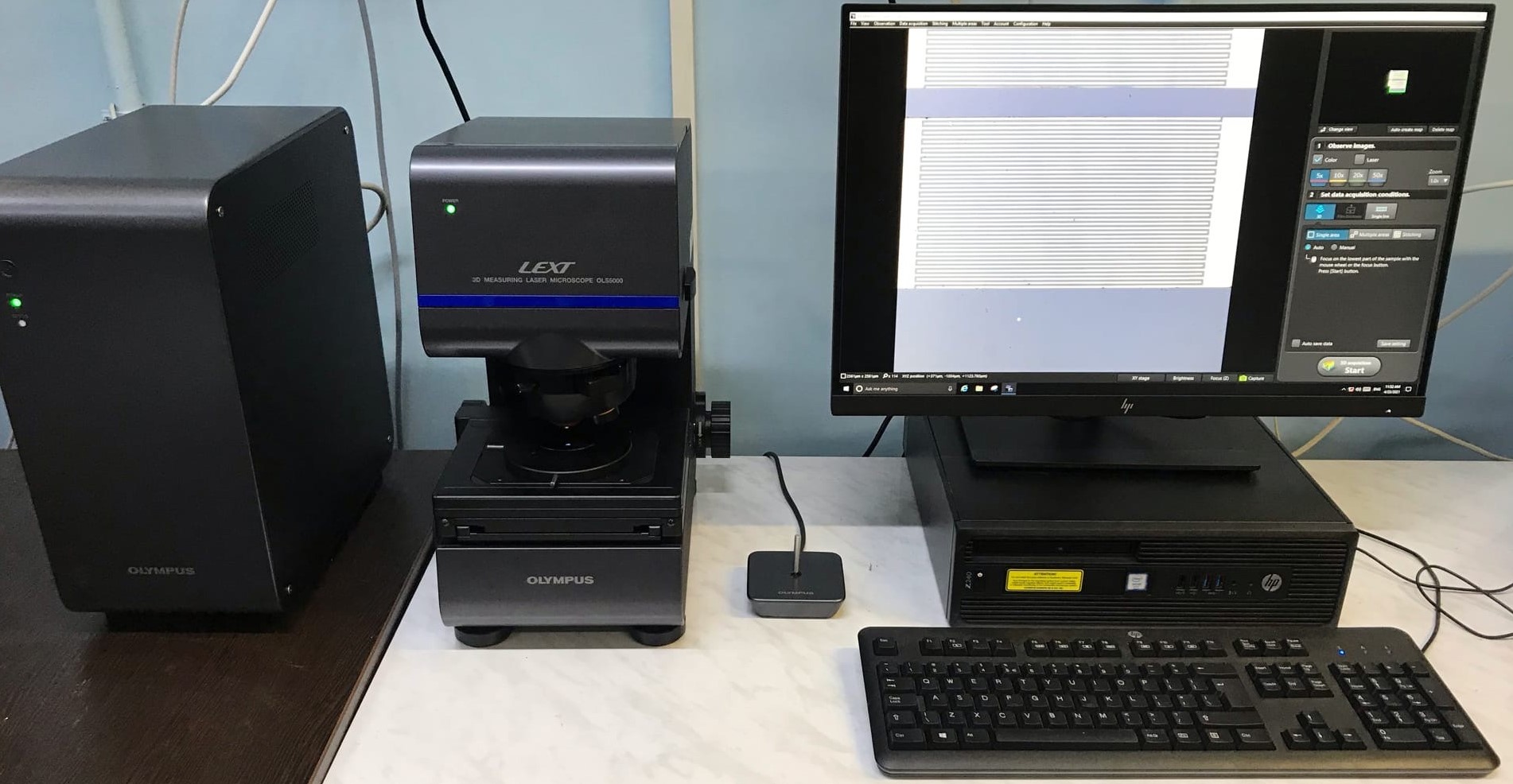

The LEXT OLS5000 laser confocal microscope is the latest development in the field of confocal microscopy. Compared to the previous model, the OLS4100 has:

Unrivaled Z-Axis Resolution – Now 6nm;

noise when measured along the Z axis – 1 nm;

new digital CMOS camera with increased fps and 4K image resolution;

speed – scanning takes 4 times less time compared to the OLS4100;

auto-correction of noise when building a model using a specially developed Smart Judge algorithm;

simplicity – panoramic 3D surface model after pressing one button;

new lenses with long working distance, corrected for 405 nm light;

new frame for samples up to 210 mm high;

guaranteed accuracy when measured on stitched images 10x lens: 5.0 + L / 100μm, 20x or more lens: 1.0 + L / 100μm (L: stitching length [μm]);

The device is designed to study the structure and surface topography of transparent and opaque samples. LEXT OLS5000 works with optical contrasting methods: brightfield, polarized light and DIC. It combines 2 microscopes – a research optical motorized microscope and a laser confocal measuring microscope for measuring linear dimensions, as well as a laser profilometer profilograph and can be used as a scanning microscope. 17280x magnification and high resolution among similar microscopes. The unique ability to study inclined surfaces with an angle of inclination up to 85.

Three methods of observing the sample:

color three-dimensional confocal (real-color confocal), highresolution confocal three-dimensional view on the height map (height data).

Multifunctional software allows you to obtain 2D and 3D images of the test sample without contact, which means that there is no mechanical effect on the test surface.

A laser microscope is used to study surface morphology down to the nanometer scale. Allows you to obtain a 3D image of the sample surface and measure such parameters as surface roughness, average thicknesses and geometric dimensions of structural elements on the surface. To eliminate external environmental influences on measurements, includes a hybrid vibration damping mechanism that eliminates the need for a dedicated rack and allows measurements on any workbench.

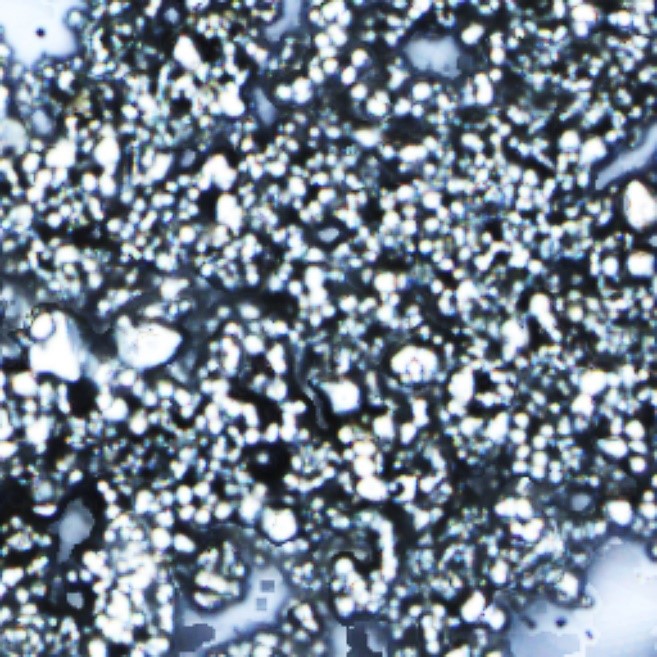

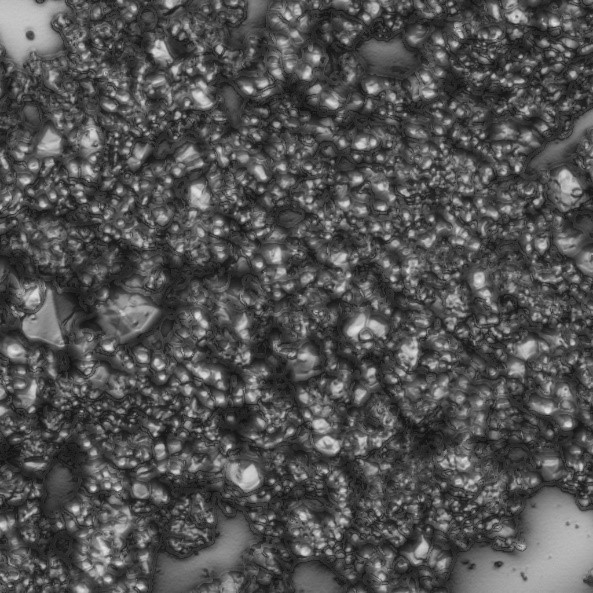

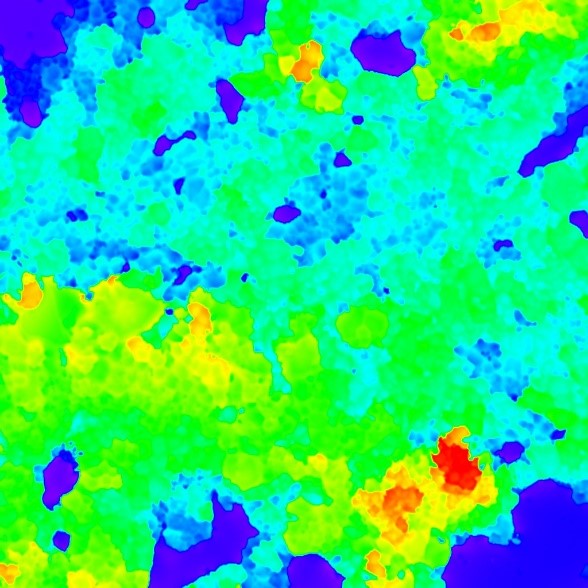

Examples of images obtained using a microscope:

Image of molybdenum microparticles planted on a glass slide, obtained in the optical mode.

Images of molybdenum microparticles obtained by laser scanning of a sample (elevation map and surface image obtained by laser scanning)